What is the Fluke Critical Asset Thermal Infrared Monitoring?

The critical thermal monitoring systems is essentially made up of three components. The fixed IR Camera including its lens options, the ThermoView Critical Asset Monitoring software which includes singe and multi-camera support, email alarms, IR and thermal viewing, archiving and alarming with Modbus TCP output to SCADA, and lastly, Weatherproof enclosures with fixed or 360-degree panning, offering full control within ThermoView software and remote monitoring of large areas.

What are the key groups that need critical asset thermal monitoring systems?

Fire Prevention

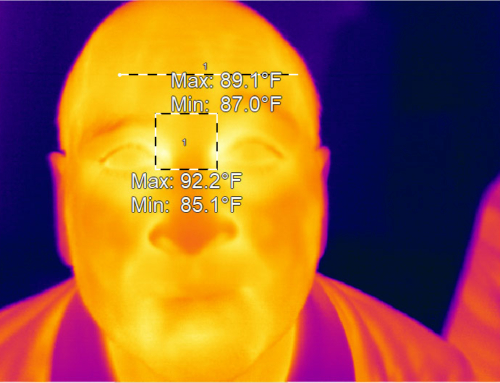

Fire prevention and hotspot detection -using continuous temperature monitoring of mission-critical equipment, facilities, or flammable material, prevents downtime due to equipment failure or fire.

The value of Hot Spot and Fire Prevention is immense. Fire can destroy multiple buildings, materials, installations, or operations quickly. The property's value destroyed during a fire can be tremendous, and the cost of life during a fire is impossible to calculate. Fire alarms alert after the fire has started, and handheld IR cameras won't catch intermittent hotspots or flare-ups. With critical asset monitoring, you can use the temperatures "rate of change" function in our software for early warning of alarm conditions to catch a potential disaster before it happens. All of these things are liabilities. Take this into consideration, and the ROI of an IR monitoring system is instantly achievable because you do not want to see this type of catastrophe within your organization.

Substation Monitoring

Substation monitoring at core business sites is most commonly used for continuous thermal image monitoring of mission-critical equipment and assets such as transformers, bushings, and capacitor banks for overheating issues.

What are the highlights of the Fluke Critical Asset Monitoring systems?

While there are many great features of the Fluke Critical Asset Monitoring systems, some of the greatest features are it's durability, the amount it can record in a single system, and It's custom software. The systems are designed for harsh environments with IP66 housings protecting from dust and water. This allows for longer-lasting usage with a reduced deterioration of the camera. The scope of recording that the Fluke Critical Asset Monitoring systems can is vast. Its ability to have multiple thermal imagers for large viewing, optional wall or pedestal mounting, allows for complete coverage of the systems.

The custom software provided has a wide range of functionalities, including IR-Fusion® technology, which has thermal and visible sighting for easy alignment and added detail on blended images. The ThermoView Critical Asset Monitoring software provides sophisticated analysis based on absolute, differential, or rate of change asset temperature conditions, which has Alarm notification through Modbus, EthernetIP, digital outputs, or email in case anything is getting out of the proper temperature ranges.